[BIO]BOARD

2023

Carnegie Mellon University

Advisor: Robert Heard

Carnegie Mellon University

Advisor: Robert Heard

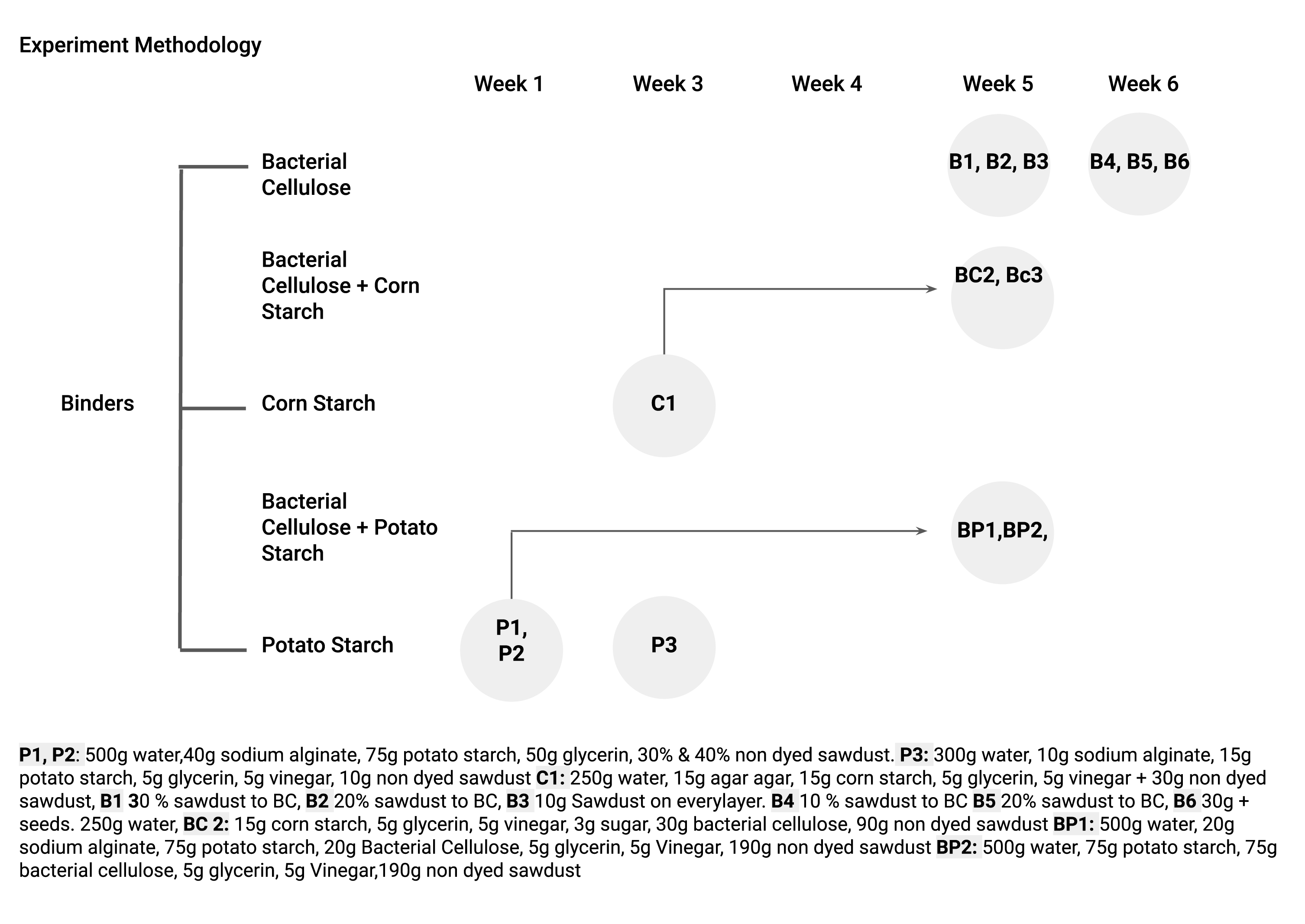

[Bio]Board is a research exploration focused on re-crafting particle board using healthier, more sustainable ingredients. Traditionally, medium-density fiberboard (MDF) is an engineered wood product made from residual sawdust bound with formaldehyde resin and wax, then formed into panels under high temperature and pressure. MDF is widely used in furniture, retail environments, and interiors. While MDF repurposes sawdust, its sustainability is compromised by the use of formaldehyde resins, which are carcinogenic and release harmful emissions when sanded or applied. Additionally, MDF is often laminated with plastics and painted to achieve desired aesthetic qualities. This project explores how alternative binders can transform particle board into a more aesthetic, healthier material.

When looking at the harm created by the binder with MDF. The goal of this project was to create a medium density fiberboard that:

1. Binding with healthier alternatives.

1. Binding with healthier alternatives.

2. Adds color to limit the use of laminates.

3. Strength & biodegrades!

Binding with healthier materials:

![]()

![]()

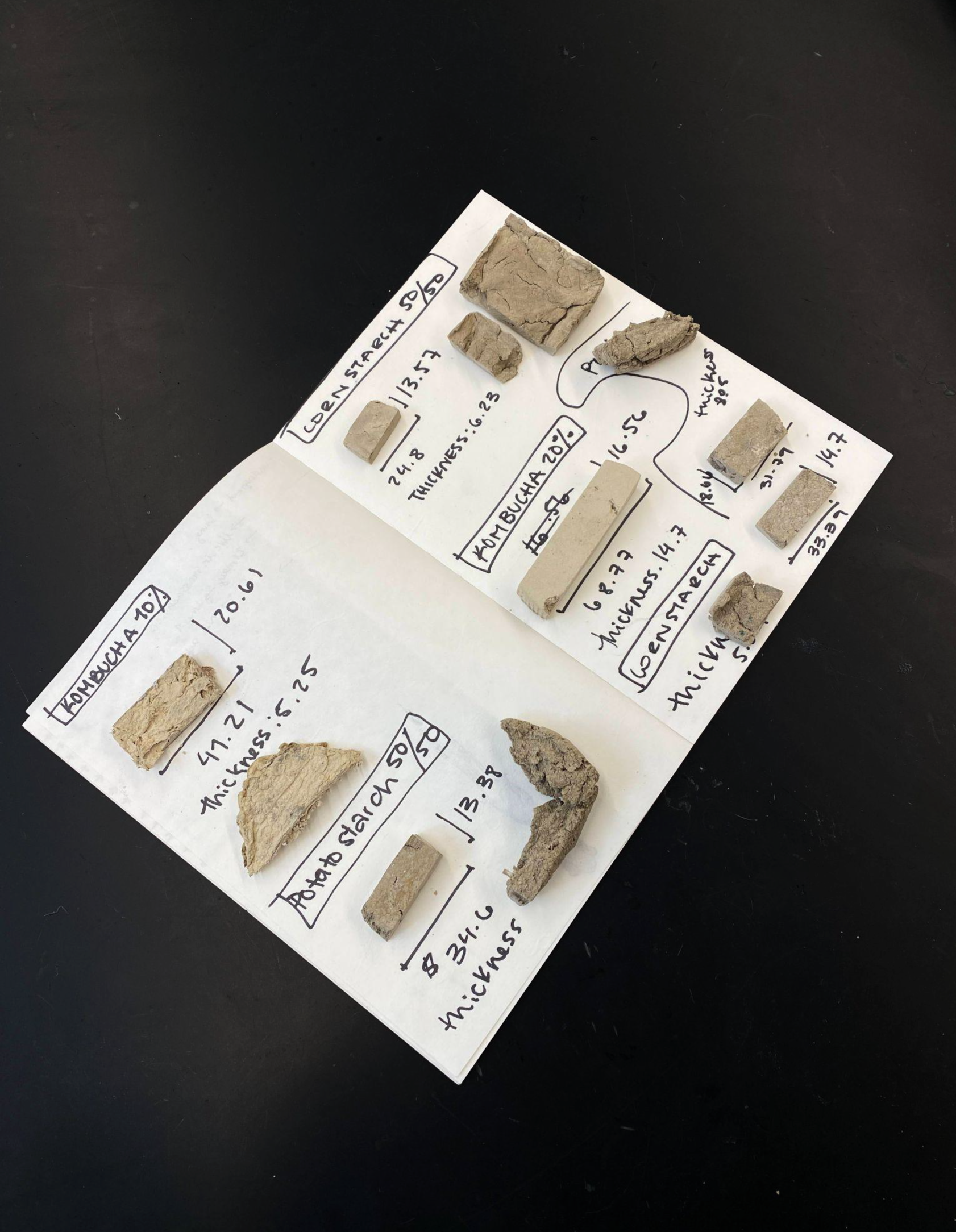

Comparative Strength:

![]()

![]()

![]()

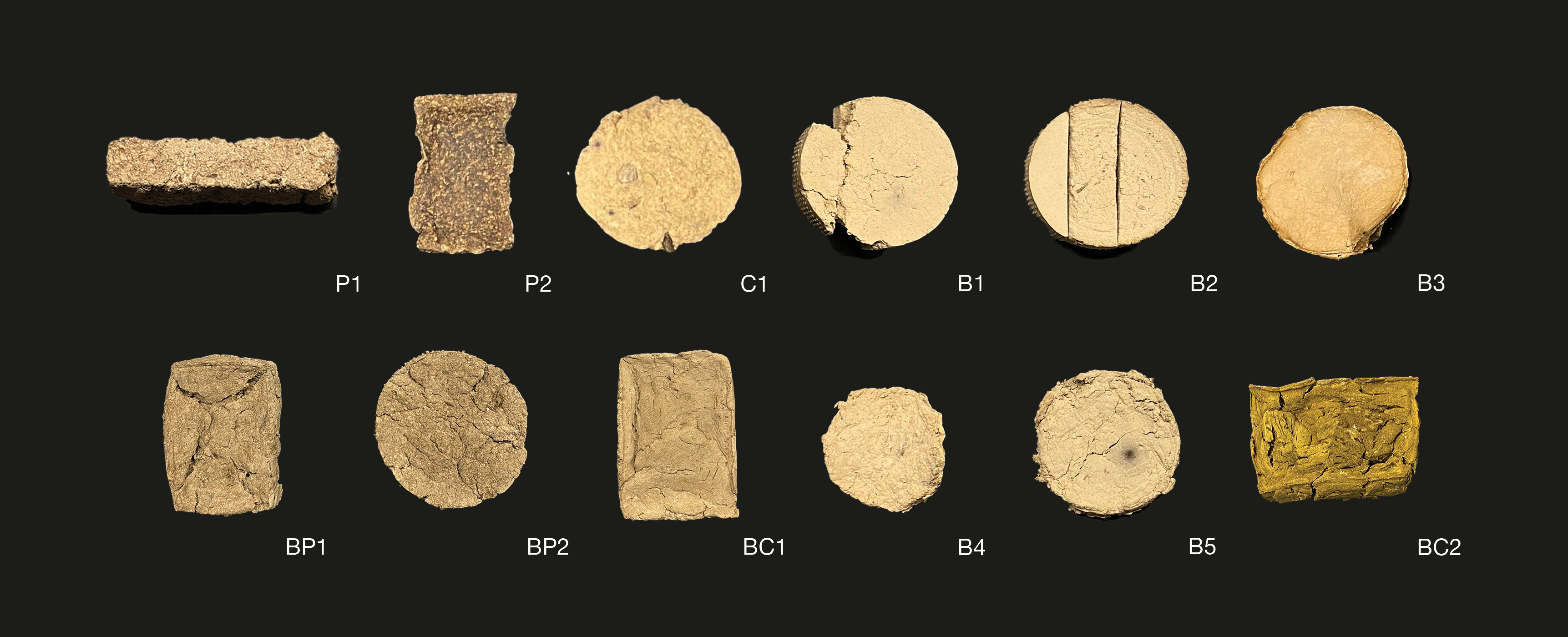

PC2, made from a combination of bacterial cellulose and potato starch bioplastic was the strongest.

PC2, made from a combination of bacterial cellulose and potato starch bioplastic was the strongest.

Image A: Color swatches created by dyeing sawdust with natural dyes. Image B: Sample with a tactile quality closest to particle board. Image C: The strongest sample, made from sawdust, potato starch bioplastic, and bacterial cellulose.

Image A: Color swatches created by dyeing sawdust with natural dyes. Image B: Sample with a tactile quality closest to particle board. Image C: The strongest sample, made from sawdust, potato starch bioplastic, and bacterial cellulose.